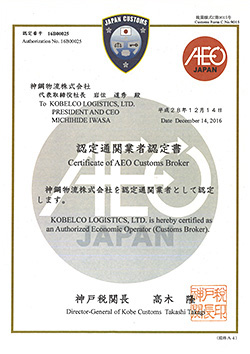

As the in-house forwarder for the Kobe Steel Group Kobelco Logistics handles global logistics and is actively working to expand overseas into growth markets going forward. In China and India, where the Group is focusing, we have established local subsidiaries in Shanghai and Chennai, respectively.

We boast a global transport track record that extends around the world, from European and Middle Eastern countries to China and Southeast Asian nations. We tap our expertise to coordinate optimal transport attuned to the particular characteristics of the products being moved and provide comprehensive logistics solutions centered on integrated operations that extend from arranging warehousing to organizing appropriate combinations of modes of transport encompassing sea, air and inland shipping.

The cargo we transport is primarily machinery or machinery-related, such as construction machinery, plant equipment, industrial machinery, and precision equipment. We provide optimal plans in terms of efficiency and cost based on detailed surveys of the local traffic, geography, and climate. We also offer door-to-door service for both imports and exports.

Menu

Menu