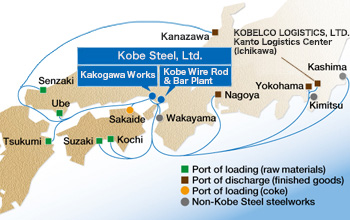

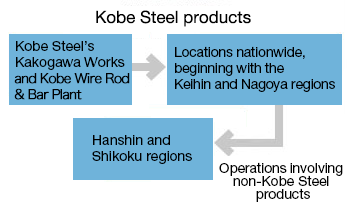

Kobelco Logistics provides loading, unloading and transport services for raw materials and steel products to Kobe Steel’s Kakogawa Works and Kobe Wire Rod & Bar Plant. In marine transport, our fleet of around 50 ships, including five owned ships such as the technologically advanced Shinzui Maru, connect unloading locations around the country and transport over 11 million tons of cargo annually. Our IT network enables the centralized management of all ships and cargo. We have also connected our unloading locations to the Internet and are raising the safety and efficiency of our integrated transport services to the top of the industry.

In inland transport, in addition to our main transport operations involving steel and industrial products and materials, we also undertake the legally compliant transport of heavy plates and outsize cargo using special vehicles.

Menu

Menu